Coffee Packaging Solutions for Modern Coffee Brands

1. Introduction: Why Coffee Packaging Solutions Matter in Today’s Market

Packaging plays a big role in the coffee industry. It works like the army of a country. If the army is strong, the country stays safe. In the same way, if the packaging is right, the coffee stays safe and fresh.

Coffee packaging solutions matter a lot in today’s market. Good packaging protects the coffee and helps keep its taste, aroma, and freshness for a longer time. When coffee is packed properly, its shelf life also increases, which is very important for brands selling both online and in stores.

Coffee inside the pack has to stay safe until it reaches the customer. But coffee faces many problems once it is packed. One big issue is oxidation. When coffee comes in contact with air, it slowly loses its flavour and smell. Another problem is moisture. Even a little moisture can spoil coffee and change its taste. Then there is sustainability pressure. Customers today want packaging that is better for the environment, and brands have to think about that too.

Advanced coffee packaging has now become a competitive part of the business. It is not only about the material or being eco-friendly. The way the packaging looks also matters a lot. When customers see coffee on a shelf or online, the pack is the first thing they notice. If the packaging looks interesting and eye-catching, people are more likely to buy it. If it looks dull or confusing, they may just ignore it and move on.

Good coffee packaging is not just a box or pouch. It is part of how a coffee brand is seen and remembered.

2. Core Functional Requirements of Coffee Packaging

Oxygen and Moisture Barrier Performance

Oxygen and moisture are the biggest enemies of coffee. If air or moisture enters the pack, the coffee slowly loses its aroma and taste. That is why low OTR (Oxygen Transmission Rate) and MVTR are important. Simply put, the lower these numbers are, the better the pack is at blocking air and moisture.

When oxygen gets inside the packaging, coffee starts to taste bad. Natural oils in coffee react with oxygen, which causes a bad smell and bad taste. By the time, this can even cause rancidity, making the coffee unsellable. This is why proper barrier packaging is not optional, it is needed.

Mono-material coffee packagings are a better solution, easier to recycle, and better for the environment. But they usually offer lower barrier protection compared to multilayer packs. Multilayer structures use different layers to block oxygen and moisture better. Brands have to balance freshness needs with sustainability goals while choosing between these options.

Gassing Problem for Freshly Roasted Coffee

Freshly roasted coffee releases carbon dioxide after it is roasted. This is a natural process and can continue for several days or even weeks. If this gas has no way to go out, the packaging can burst.

This is where one-way degassing valves help. These valves allow CO₂ to go out of the pack but do not let air come back in. They are mainly used for freshly roasted whole beans and sometimes for ground coffee. Without a valve, packing fresh coffee becomes risky.

Valve placement also matters a lot. In flat pouches, the valve is usually placed near the centre so gas can escape evenly. In stand-up pouches, it is often placed on the front panel above the coffee level. Wrong placement can reduce valve performance and affect how the pack looks.

Mechanical Strength and Seal Integrity

Coffee packaging must be strong enough to handle filling, transport, and storage. Heat seal strength is important so the pack does not open during handling. Drop resistance and puncture resistance also matter, especially for e-commerce deliveries where packs are moved a lot.

Many packaging failures happen at the seals. Weak seals, uneven sealing, or contamination near the seal area can cause leaks. Another common issue is poor material choice, which can tear easily under pressure.

Seal consistency is very important on automated filling lines. If the seal is not uniform, some packs may pass while others fail. This leads to wastage, returns, and unhappy customers. A reliable packaging setup helps avoid these problems and keeps operations running smoothly.

3. Sustainable Coffee Packaging Solutions: Materials and Certifications

Compostable vs Recyclable Packaging Structures

Compostable packaging is made in industrial composting setups. It’s good for the environment, but it does not protect coffee as long as regular plastic packs. Compostable material can dig and disappear.

Recyclable packaging uses PE or PP mono materials. These packs can be recycled again and again and they keep coffee safe from air and moisture for longer. The only downside is that they don’t just disappear like compostable ones, but at least the coffee stays fresh.

Compostable packs are mostly useful for local sales or small batches, where coffee will be consumed quickly. For bigger storage or shipping to other cities or countries, recyclable packs will be better.

Certifications and Compliance Standards

If you are using compostable packs, they must have standards like EN 13432 or ASTM D6400. This proves that the packaging will actually break down and not just sit in the dustbin. Without these, saying “compostable” is just words.

Food safety is also very important. Materials should follow FDA or EU 10/2011 standards so nothing harmful mixes with coffee. Customers trust the brand more if the packaging is safe for food.

4. Coffee Packaging Formats and Use-Case Applications

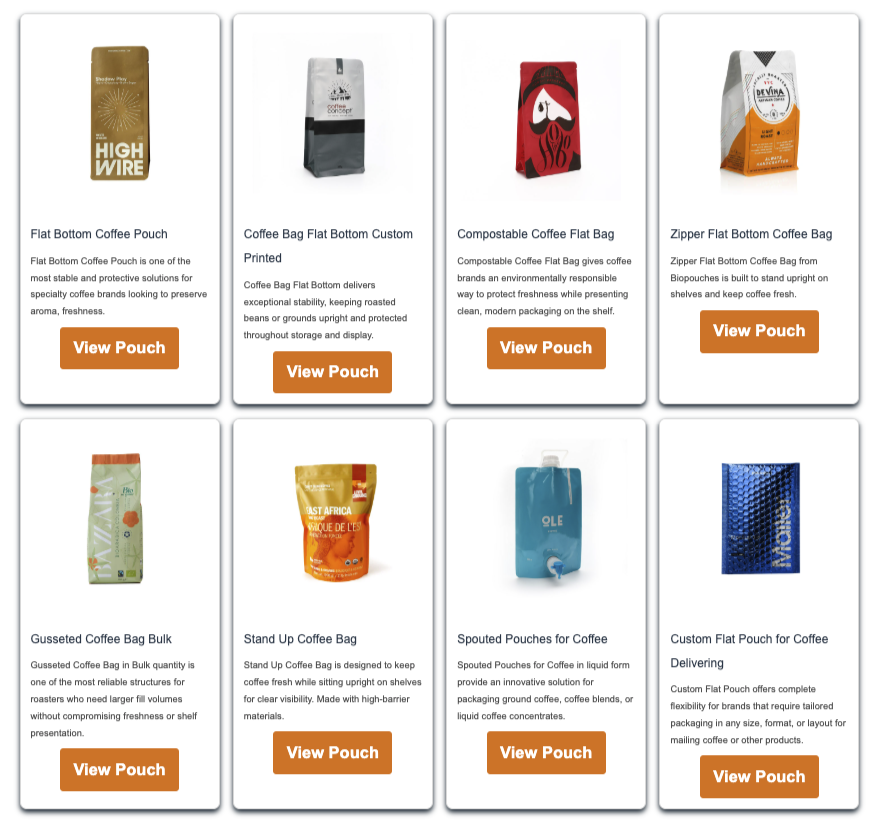

Flat Bags for Ground and Whole Bean Coffee

Flat bags are simple and very common for coffee. They don’t take much space, so shipping and storage is easy. For small shops or online orders, they are very convenient.

On the shop shelf, flat bags should look nice and clear. Even simple design works if it’s easy to read and catches attention.

If you want an eco-friendly option, compostable coffee flat bag work well. They keep coffee fresh for a short time and are good for local sales or direct-to-customer delivery.

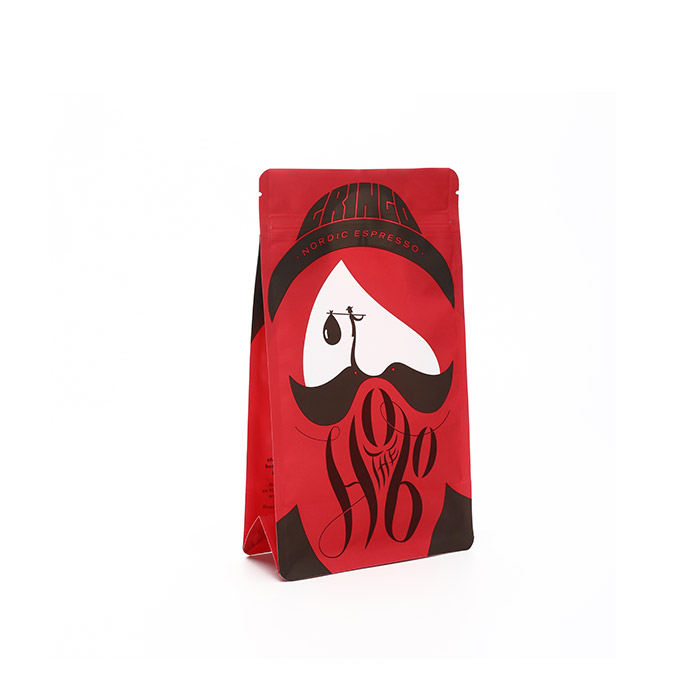

Compostable Coffee Flat Bag for Sustainable Coffee Packaging

| Brand Name | BIOPOUCHES |

| Material | Compostable |

| Thickness | 130 microns |

| Type | Customise |

| Place of Origin | ShangHai, China |

| Surface Handling | Gravure printing |

| Sealing & Handle | Zipper Top |

| Custom Order | Accept |

| Usage | Packaging printing bags for coffee |

| Size | Customise |

| Minimum Order Quantity | 1000 |

Stand-Up Pouches and Resealable Systems

Stand-up pouches are very popular because people can keep them on the kitchen shelf and use again. The zipper helps to keep coffee fresh even after opening.

There are different types of zippers. Some close very tight, some are loose. So it’s better to test them before using so coffee doesn’t go stale.

You can also make these pouches with compostable materials. But the zipper has to match the material. Not all compostable zippers work well, so brands need to check carefully.

5. Printing, Branding, and Technical Customization

Print Technologies for Coffee Packaging

There are different ways to print on coffee packs. Digital printing is fast and good for small batches. Rotogravure and flexographic printing are better for bigger batches and give sharper prints.

If you are using compostable films, ink needs to stick properly. Some inks don’t hold well and can peel off. Also, colors should stay bright and not fade while sitting on the shelf for months.

Customization for Brand Identity and Regulatory Needs

Coffee packs need certain information on them, like batch codes, roast dates, and origin. Variable data printing helps put this info easily on each pack.

You also need labels for roast level, type of coffee, and sustainability claims. If you are selling a premium brand, design can be classy and simple. For mass-market coffee, design should be clear and easy for customers to understand.

6. Operational Considerations for Coffee Roasters and Brands

Filling Line Compatibility

Coffee packs can be filled manually or with automatic machines. Automatic lines are faster but need proper setup.

Compostable films need careful heat sealing. Too much or too little heat can spoil the pack. Checking temperature windows is very important.

During production changeovers, some material gets wasted. Planning and careful setup can reduce waste and save money.

Storage, Transportation, and Shelf-Life Testing

Coffee packs need proper testing to see how long coffee stays fresh. Accelerated shelf-life tests help predict this in a few weeks instead of months.

During transport, coffee faces humidity and temperature changes. Proper storage and packing help keep coffee safe.

Inventory rotation is also important. First-in, first-out rule makes sure older coffee sells first and stays fresh for customers.

Visit our Pinterest page for interesting designs and examples.

Latest News